Tormek

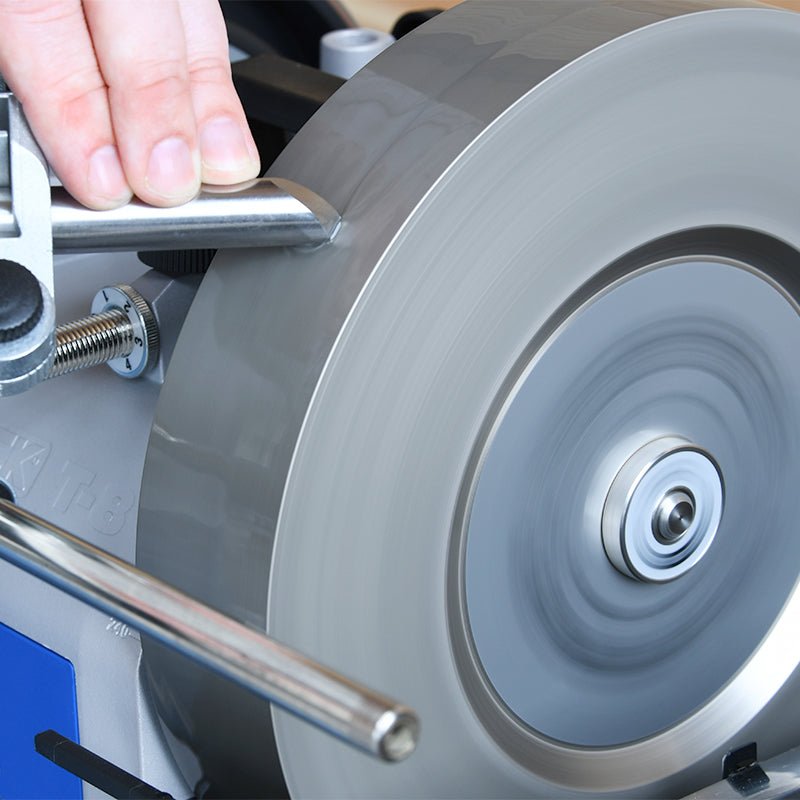

Tormek, already has one of the most versatile and comprehensive sharpening systems, now has even more potential. These Tormek diamond grinding wheels offer huge benefits: exceptional durability and the ability to sharpen on the flat side as well as the periphery. Used together with MB-100 multi base you can sharpen on the side of the diamond wheel to produce a completely flat bevel, which may be preferable in some cases. In addition, these diamond grinding wheels will never require dressing and will always retain their original diameter.

The quality of the diamond surface provides a high quality and consistent finish to your edge tools. Diamond is the world's hardest material and almost twice as hard as cubic boron nitride (CBN). Diamond's extreme hardness and durability make it the ultimate abrasive material for sharpening. Although the wheels work perfectly well dry, Tormek recommend using water as it gives a much better result. The Tormek Fine diamond grinding wheel has a grit size of 600 mesh. It combines efficient steel removal with smooth surface finish making it the perfect versatile wheel. The Fine stone is ideal for putting a high quality sharp edge on a regularly sharpened blade. The wheel comes with 150ml of ACC-150 Anti-Corrosion Concentrate.

You can sharpen all types of material, which include steel, ceramic, and tungsten carbide. These wheels fit Tormek T-8, Tormek T-7 and previous models Tormek 2000 - 2006 with a 250mm stone diameter.

Key Features

- Exceptional durability; never needs re-truing

- Extra Fine 1,200 grit for refined and polished edge

- Sharpens on the flat side as well as the periphery

Warranty

Shipping & Returns

Shipping & Returns